Everything From a Single Source – You Can Rely on That.

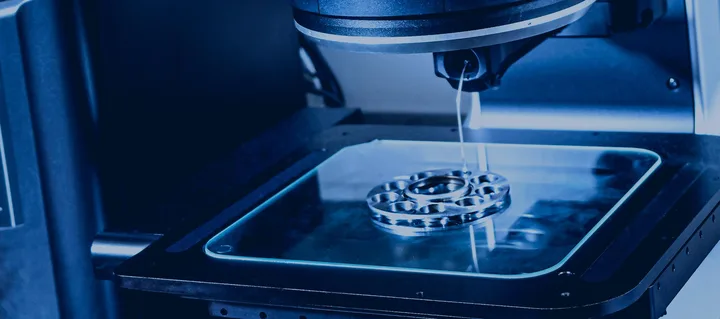

Feinstanz AG is a traditional Swiss company whose products are widely recognised in the metal processing industry for highest quality and precision. We use state-of-the-art technologies, innovative methods and highly trained, experienced employees to realise the individually optimal and most efficient solutions for our customers. Together we develop and produce complex and customised products that meet the highest requirements.

In more than 60 years of company history, Feinstanz AG has developed outstanding expertise that is trusted by international customers from a wide range of industries. The industries served by Feinstanz AG include the automotive industry, kitchen and furniture manufacturers, mechanical engineering companies and specialists in building technology and HVAC. Our expertise and experience enable us to provide our clients with the best possible advice throughout the entire course of a project and to monitor a product from the idea to the start of production. In doing so, we work closely with our customers and are by their side as a competent partner right from the product idea stage. In this way, we master challenges together and realise complex and high-quality products and components. We produce safely, reliably and efficiently - from serial production to the delivery of complete assemblies.

Swiss quality for the international market

Feinstanz AG brings Swiss quality to the whole world. As an internationally active company, we support renowned customers around the globe. Our workforce of around 70 employees are passionate solution implementers who have a great deal of technical know-how and creative ideas and are committed to the success of our partners and clients. In order to maintain this expertise and train our own specialists, we invest specifically in the training of our apprentices in various apprenticeships. Feinstanz AG specialises in working in close cooperation with customers to develop individual, customer-specific solutions.

Innovation and technological progress

Sustainability, economic efficiency and the success of our customers are at the heart of everything we do at Feinstanz AG. That’s why the ongoing optimisation of processes and technology has always been part of our corporate culture. This continuous development in the process engineering areas combined with modern tools and machinery enable us to guarantee the best possible quality.

Competence

We are committed to the highest levels of precision and safety. We monitor and ensure the required quality throughout the entire manufacturing process. Our quality management system is certified according to IATF 16949. We highlight our competence with our management certifications.

News

Complete satisfaction of our employees.

Contact

Do you have questions?

Contact us, we are happy to help!